At SCS we are acutely aware of the vital role that springs play in making the world work, from saving lives through medical device applications to feeding the world with agricultural machinery to power generation and many more areas and industries. The products and equipment being produced by our customers are always advancing and in 40+ years of manufacturing we have seen how technology has driven these advancements. That is why SCS continues to invest in cutting-edge equipment and technology to continually deliver world-class custom springs to our customers. Recently SCS have invested in 3 new important pieces of equipment: Ultrasonic Cleaning, Laser Welding and Laser Measurement.

Read on to learn more about how these investments will build on our world-leading standards in spring production.

Ultrasonic Cleaning Equipment

Removal of all possible contaminants is essential in the production of springs, particularly when it comes to the use of springs for medical purposes. SCS have invested in the highest quality of ultrasonic cleaning equipment. Using ultrasonic waves, the machine provides highly advanced cleaning to remove dirt, oxidation and contamination from the surface of an item with intense vibrations.

The intricate springs which SCS manufactures require delicate and thorough cleaning while maintaining their structural integrity and functionality. In medical device production, where cleanliness and sterility are paramount, our new state-of-the-art equipment plays a critical role in ensuring compliance with the stringent hygiene standards that our customers require. By removing contaminants at a microscopic level, ultrasonic cleaning helps to mitigate the risk of contamination and cross-contamination, making spring components suitable for use in critical medical devices with confidence in their cleanliness and safety.

The adoption of ultrasonic cleaning technology in spring manufacturing not only enhances product quality and performance but also contributes to the reliability and safety of devices where these springs are utilised.

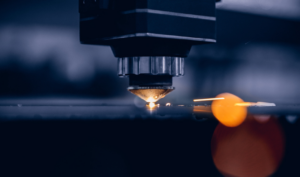

Laser Welding Equipment

SCS latest investment in laser welding equipment has come in the form of the Winlaser by AlphaLaser. Laser welding technology uses a laser beam as a high-concentrated heat source to join or cut materials. SCS understand that our customers are creating high-spec products and equipment that require many intricate components which is why we are dedicated to delivering high-quality custom spring solutions as speedily and efficiently as possible. This type of machine can be used to speed up production and give our customers a fast and reliable experience. This machinery also allows for higher levels of precision with adjustable components such as the laser head, the microscope attachment, various operating modes and the working chamber.

Springs produced with laser welding equipment offer enhanced durability and reliability, as the laser welding process minimises heat-affected zones and reduces the risk of distortion or material degradation. The external display allows for greater observation of the welding process so our expert engineers can perfect each type of spring manufactured by SCS. These features result in a precision manufacturing process for the creation of springs with customised geometries and tailored mechanical properties, catering to specific application requirements across aerospace, medical, and other sectors.

Laser Measurement Equipment

New Laser Measurement Equipment acquired by SCS will provide the highest level of accuracy and scanning capability when it comes to the precise nature of measurement in detailed spring designs. The equipment made by Mitutoyo is a non-contact measuring system allowing for microscopic inspection of workpieces even if they are small, fragile, at various temperatures or even in motion.

The use of the cutting-edge laser scan micrometer along with an adjustable workstage allows high-accuracy measurement inspection of fine wires. Accurate measurement of wire diameter, alongside other parameters such as tensile strength and surface finish, directly influences the spring’s mechanical properties, including load-bearing capacity, elasticity, and fatigue resistance. Additionally, precise measurement allows for consistency in spring dimensions, ensuring uniformity and compatibility in assembly and application.

Custom Spring Design with SCS

With our specialist team, we have the know-how and capability to support your development and production. We can design and make products based on wire diameters down to 0.3mm. We don’t just understand springs, we also understand the industries in which our customers operate and the unique demands of each area. That is why we pride ourselves on being fast at responding, fast at developing ideas, fast at prototyping, and willing and able to alter our production schedules to fit your needs.

Looking for advice on springs for your project? Discuss your requirements with our highly specialised team today. Contact us for experienced advice and solutions in spring design.